Thickened Disposable Environmental Protection Paper Cup Single Plate Machine

Send Inquiry

The Thickened Disposable Environmental Protection Paper Cup Single Plate Machine from Yongbo Factory, as a multi-functional automatic molding machine, is designed for hassle-free operation and efficient production. This machine is perfectly suited for crafting various paper containers, including beverage cups, tea cups, coffee cups, promotional paper cups, ice cream cups, and other food cone-shaped items, all through a streamlined production process.

Thickened Disposable Environmental Protection Paper Cup Single Plate Machine Basic information

|

Model number |

YB-S100 |

brand |

YongBo Machinery |

|

speed |

100-110min/pcs |

country |

China |

|

trademark |

Customized |

After sale |

Online |

|

transport |

Wooden Case |

warranty |

1 year (non-human reason) |

Yongbo Machinery Thickened Disposable Environmental Protection Paper Cup Single Plate Machine Machine data

|

Model number |

Yongbo thickened paper cup machine disposable environmental protection paper cup single plate machine automatic paper cup machine |

|

Paper cup size |

2-12oz (Mold replaceable, Max cup height: 115mm, Max bottom width: 75mm) |

|

Operating speed |

100-110 PCS/min (speed is affected by cup size, paper quality thickness) |

|

Raw material |

Single or double sided PE coated paper (suitable for hot and cold drink cups) |

|

Gram weight of paper |

150-350 grams per square meter |

|

voltage |

50/60HZ,380V/220V |

|

Total power |

5 kw |

|

Gross weight |

2500 kg |

|

Machine size (length * width * height |

2200*1350*1900mm (machine size) 900*700*2100mm (Cup receiver size) |

|

Cup body bonding mode |

Ultrasonic wave |

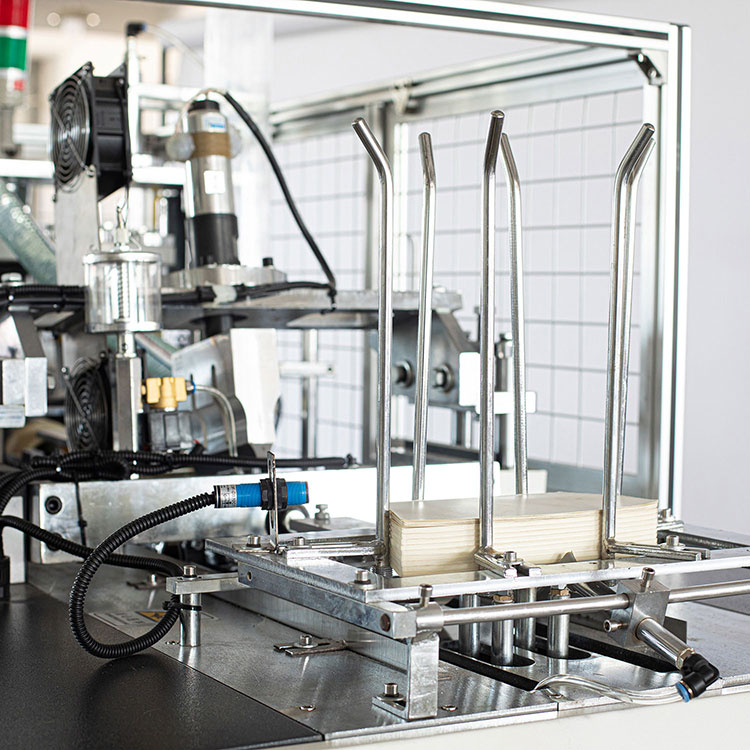

Yongbo Machinery Thickened Disposable Environmental Protection Paper Cup Single Plate Machine Flat display

Yongbo Machinery Thickened Disposable Environmental Protection Paper Cup Single Plate Machine Product introduction

The S100 paper cup machine is a multi-station automatic forming system that incorporates an automatic lubrication system, an open CAM interface, and a gear motor. Operating on a single disk and single axis configuration, it seamlessly integrates processes such as automatic paper feeding, sealing (including gluing the cup walls), oil filling, bottom filling, heating, knurling, rolling, and more. Alongside these functions, it also offers photoelectric detection, fault alarms, and counting capabilities. This machine is the ultimate choice for manufacturing paper beverage cups, tea cups, coffee cups, advertising paper cups, ice cream paper cups, or any other food cone-shaped containers.

Investment Prospects of paper cup Use and Production:

【S100 Paper cup machine 】

This machine is suitable for domestic market paper cup, advertising paper cup, ice cream paper cup, coffee cup and other restaurants, high-end hotels for coffee cups, wine glasses, and corporate advertising cups.

Investment prospects: The market demand is large, adapt to the needs of social development, paper container will be banned plastic paper cup. The machine covers an area of less, less power consumption, low labor intensity, simple operation (a person can operate), and investment needs less capital, small risk, very suitable for family investment and entrepreneurship.

Investment Outlook: Given the vast market demand and societal push towards environmental sustainability, paper containers are poised to replace plastic cups. The S100 paper cup machine is an optimal choice due to its compact design, low power consumption, reduced labor intensity, user-friendly operation (requiring only one operator), minimal capital investment, and low-risk profile. It is highly recommended for families considering investment or entrepreneurship.

Functional Highlights and Part of the Manufacturing Process: The machine employs stepless frequency conversion control, making it exceptionally versatile and easy to adjust production speeds. Additionally, the photoelectric monitoring system ensures automatic fault detection, alarm, and accurate counting, further enhancing its operational efficiency and reliability.

Photoelectric monitoring: automatic fault alarm, counting.

According to customer requirements design and production mold, by changing the mold can produce a variety of sizes of paper cups, to achieve a machine with multiple products.

Based on customer specifications, we customize molds for production, allowing for the creation of various sizes of paper cups with a single machine for multiple products.

1. The machine automatically transforms the printed fan-shaped paper (the unfolded shape of the cup) into the desired paper cup form.

2. The cup walls of the paper cup are glued using hot forming techniques, tailored specifically for PE-coated paper.

3. The bottom of the paper cup is crafted from web paper, which is automatically fed and cut to size.

4. The body and bottom of the cup adhere to each other through hot air blowing, ensuring a secure bond.

5. Knurling involves mechanically rolling a layer of impressions onto the bottom of the paper cup for enhanced stability.

6. Crimping refers to the shaping of the paper cup's mouth for a finished and appealing appearance.

|

|

|

Ten station cup membrane body |

Bottom cover and crimped edges |

|

|

|

CAM drive system |

Integrated workbench |

Production display