Paper Cup Forming Machine

Send Inquiry

PDF DownLoad

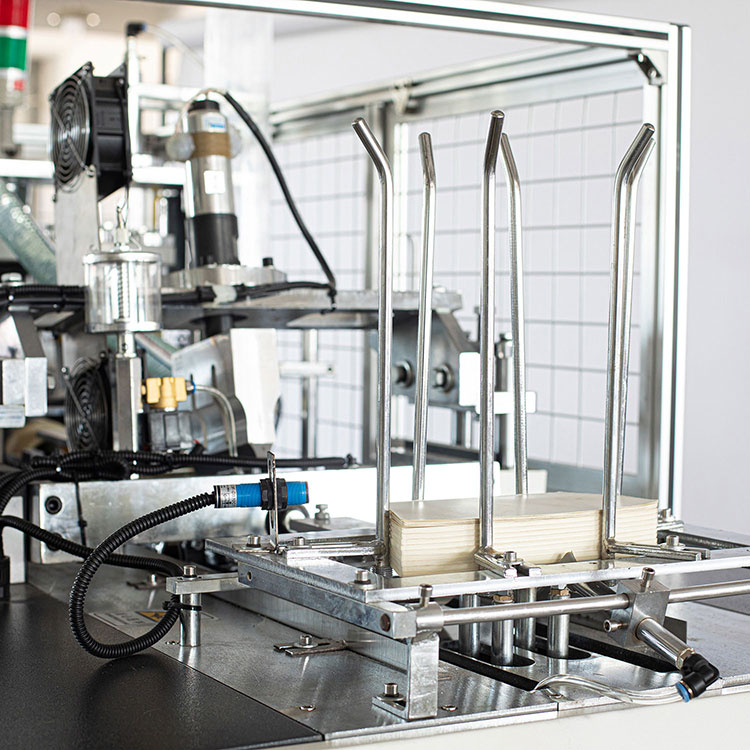

The recently revamped Yongbo Paper Cup Forming Machine represents the epitome of automated paper cup production. It seamlessly integrates various functions, including automatic paper feeding, an anti-withdrawal mechanism for precise positioning, ultrasonic welding, the transfer of paper fans using a precision manipulator, silicone oil lubrication, bottom punching, folding, pre-heating, knurling, and cup discharge. This machine, which underwent rigorous research and development by our company, has undergone comprehensive technical enhancements to further bolster its stability and reliability, ensuring it functions as a top-notch cup cake forming solution.

Yongbo Machinery cup cake forming machine Feature And Application

1. The control panel of this paper cup maker is equipped with high-quality switches, a temperature controller, and a speed converter. This allows for easy operation of the machine through the use of the panel.

2. The updated design of this paper cup maker includes an additional bottom heating system, which improves the sealing effect of the paper cups compared to the old design.

3.The operation board of this paper cup maker is made of a single piece of thick and sturdy steel, making it highly durable and easy to clean.

Yongbo Machinery cup cake forming machine Details

1.The whole cup cake forming machine adopts automatic oil lubrication system( oil circulation system is including oil motor,filter, copper pipe )which makes all gear moving parts working at high speed much more smoothly and greatly Improve the service life of spare parts.

2.This cup cake forming machine is independently developed by Yongbo Machinery, it can produce paper cups of different sizes through a series of continuous processes, including more than 2 times of automatic paper feeding, paper anti-return device (to ensure accurate positioning), ultrasonic welding, using magic Hand conveyed paper fan, lubricated with silicone oil, punched at the bottom, folded at the bottom, preheated at the bottom, knurled at the bottom, and out of the cup. After comprehensive technical improvement, the machine stability has been improved.

3.The disposable paper cup machine steel plate presses the bottom paper to make the paper feeding more stablyand smoothly.